Description:

This valve is an adjustable valve with simple structure. It also can be used in low pressure pipe as switch control. It has the throttling and cutting off function in corrosive, non-corrosive fluid medium pipelines. Butterfly valve is applicable to generator, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting, and power generation, environmental protection, building water supply and drainage and other engineering system.

Features:

Butterfly valve features simple structure, small volume, light weight, less material consumption, small installation size, small drive moment and simple operation. It also has good flow regulating function and well closing sealing performance. Its reliability and other performance indicators are up to higher level. This butterfly valve has small flow resistance when being opened fully. And it has sensitive flow control when being opened between 15o and 70o. Therefore, this valve will be widely applied to flow control with large caliber. Most butterfly valves can be used to the medium with suspended solids. According to the strength of the seals, this butterfly valve can also be used for powder and grain medium.

Application:

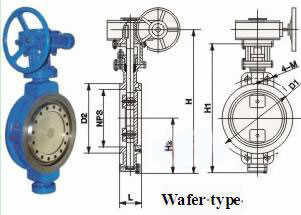

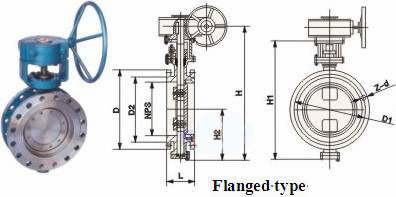

815, 830 series butterfly valve is widely used in petroleum, chemical, industrial environment, water treatment, high-rise buildings, water supply and drainage pipeline, etc. The main structures are wafer type and flange type. And the structure characteristics of 815, 830 L series butterfly valve are that the rim of valve has convex and the design is screw holes single flange structure. Due to the use of Three Eccentric Structure, this butterfly valve has reliable sealing performance, which can ensure the butterfly plate does not contact seal seat when that opens. It can ensure the uniform load of seal seat and prolong the life. It ensures reliable seal, high temperature resistant, well wear resistance, well corrosion resistance, etc.

Model Illustration of Butterfly Valve Series:

|

|

Standard of Butterfly Valve Series:

Design standard: API609-83

Flange connection: ANSI B 16.5

Structural length: ANSI B 16.10-1992

Pressure test: API 598-82

Technical Parameters of Butterfly Valve:

| Nominal diameter | DN(mm) | 830W | 830L |

| 2"~36" | 2"~36" | ||

| Nominal pressure | PN(Mpa) | 150Lb | 300Lb |

| Test pressure | Strength test | 3.0 | 7.5 |

| Seal test | 2.2 | 5.5 | |

| Suitable medium | Water, steam, oil, and others | ||

| Suitable temperature | -29℃~425℃ | ||

Part Materials of Butterfly Valve:

| Item | Materials |

| Body | WCB, 304, 316, 316SS, CF8M |

| Plate | WCB, 304, 316, 316SS, CF8M |

| Stem | 316, 2Cr13, 1Cr18Ni9Ti |

| Seal ring | 316, Fluoroplastics |

| Packing | flexible graphite, fluoroplastics |

815W Series ANSI:

| Nominal diameter | Structure length (standard) |

Outline dimensions (reference value) |

Connection size (standard) |

Reference weight (kg) |

|||||||

| L | L1 | H | H0 | D | D1 | D2 | M | Z-d | |||

| 2" | 50 | 43 | 108 | 110 | 345 | 152 | 120.5 | 92 | M18 | 4-19 | 9 |

| 3" | 80 | 49 | 114 | 125 | 380 | 190 | 152.5 | 127 | M18 | 4-19 | 11 |

| 4" | 100 | 56 | 127 | 145 | 415 | 229 | 190.5 | 157 | M18 | 8-19 | 13 |

| 5" | 125 | 64 | 140 | 165 | 455 | 254 | 216 | 186 | M20 | 8-22 | 16 |

| 6" | 150 | 70 | 140 | 175 | 545 | 279 | 241.5 | 216 | M20 | 8-22 | 26 |

| 8" | 200 | 71 | 150 | 210 | 645 | 343 | 298.5 | 270 | M20 | 8-22 | 34 |

| 10" | 250 | 76 | 160 | 250 | 695 | 406 | 362 | 324 | M24 | 12-25 | 51 |

| 12" | 300 | 86 | 178 | 285 | 830 | 483 | 432 | 381 | M24 | 12-25 | 72 |

| 14" | 350 | 92 | 190 | 320 | 900 | 533 | 476 | 413 | M27 | 12-29 | 106 |

| 16" | 400 | 102 | 216 | 355 | 980 | 597 | 540 | 470 | M27 | 16-29 | 133 |

| 18" | 450 | 114 | 222 | 380 | 1030 | 635 | 578 | 533 | M30 | 16-32 | 176 |

| 20" | 500 | 127 | 229 | 415 | 1110 | 699 | 635 | 584 | M30 | 20-32 | 190 |

| 24" | 600 | 154 | 267 | 475 | 1305 | 813 | 749.5 | 692 | M33 | 20-35 | 394 |

| 30" | 750 | 165 | 292 | 580 | 1525 | 985 | 914 | 857 | M33 | 28-35 | 476 |

| 32" | 800 | 190 | 318 | 630 | 1585 | 1060 | 978 | 914 | M39 | 28-41 | 618 |

| 36" | 900 | 203 | 330 | 680 | 1765 | 1168 | 1085 | 1022 | M39 | 32-41 | 762 |

815L Series ANSI:

| Nominal diameter | Structure length (standard) |

Outline dimensions (reference value) |

Connection size (standard) |

Reference weight (kg) |

|||||

| L | H | H0 | D1 | D2 | M | Z-d | |||

| 6" | 150 | 70 | 175 | 545 | 241.5 | 216 | M20 | 8-22 | 28 |

| 8" | 200 | 71 | 210 | 615 | 298.5 | 270 | M20 | 8-22 | 36 |

| 10" | 250 | 76 | 250 | 695 | 362 | 324 | M24 | 12-25 | 53 |

| 12" | 300 | 86 | 285 | 830 | 432 | 381 | M24 | 12-25 | 74 |

| 14" | 350 | 92 | 320 | 900 | 476 | 413 | M27 | 12-29 | 110 |

| 16" | 400 | 102 | 355 | 980 | 540 | 470 | M27 | 16-29 | 138 |

| 18" | 450 | 114 | 380 | 1030 | 578 | 533 | M30 | 16-32 | 180 |

| 20" | 500 | 127 | 415 | 1110 | 635 | 584 | M30 | 20-32 | 196 |

| 24" | 600 | 154 | 475 | 1305 | 749.5 | 692 | M33 | 20-35 | 400 |

| 30" | 750 | 165 | 580 | 1525 | 914 | 857 | M33 | 28-35 | 482 |

| 36" | 900 | 203 | 680 | 1765 | 1085 | 1022 | M39 | 32-41 | 488 |

830W Series ANSI:

| Nominal diameter | Structure length (standard) |

Outline dimensions (reference value) |

Connection size (standard) |

Reference weight (kg) |

||||||||

| L | L1 | H | H0 | D | D1 | D2 | M | Z-d | ||||

| 2" | 50 | 43 | 108 | 110 | 345 | 165 | 127 | 92 | M18 | 8-19 | 9 | 20 |

| 3" | 80 | 49 | 114 | 125 | 380 | 210 | 168 | 127 | M20 | 8-22 | 12 | 29 |

| 4" | 100 | 56 | 127 | 145 | 415 | 254 | 200 | 157 | M20 | 8-22 | 13 | 35 |

| 5" | 125 | 64 | 140 | 165 | 455 | 279 | 235 | 186 | M20 | 8-22 | 18 | 40 |

| 6" | 150 | 70 | 140 | 175 | 545 | 318 | 270 | 216 | M20 | 12-22 | 28 | 81 |

| 8" | 200 | 71 | 150 | 210 | 645 | 381 | 330 | 270 | M24 | 12-26 | 37 | 94 |

| 10" | 250 | 76 | 160 | 250 | 695 | 445 | 387 | 324 | M27 | 16-29 | 56 | 158 |

| 12" | 300 | 86 | 178 | 285 | 830 | 521 | 451 | 381 | M30 | 16-32 | 79 | 183 |

| 14" | 350 | 92 | 190 | 320 | 900 | 584 | 514 | 413 | M30 | 20-32 | 116 | 239 |

| 16" | 400 | 102 | 216 | 355 | 980 | 648 | 571 | 470 | M33 | 20-35 | 146 | 302 |

| 18" | 450 | 114 | 222 | 380 | 1030 | 711 | 628 | 533 | M33 | 24-35 | 193 | 346 |

| 20" | 500 | 127 | 229 | 415 | 1110 | 775 | 686 | 584 | M33 | 24-35 | 209 | 434 |

| 24" | 600 | 154 | 267 | 475 | 1305 | 914 | 813 | 692 | M39 | 24-41 | 433 | 638 |

| 30" | 750 | 165 | 292 | 580 | 1525 | 1092 | 997 | 857 | M45 | 28-49 | 523 | 788 |

| 36" | 900 | 203 | 330 | 680 | 1765 | 1270 | 1168 | 1022 | M50 | 32-53 | 838 | 1146 |

830L Series ANSI:

| Nominal diameter | Structure length (standard) |

Outline dimensions (reference value) |

Connection size (standard) |

Reference weight (kg) |

|||||

| L | H | H0 | D1 | D2 | M | Z-d | |||

| 6" | 150 | 76 | 175 | 545 | 270 | 216 | M20 | 12-22 | 29 |

| 8" | 200 | 89 | 210 | 615 | 330 | 270 | M24 | 12-26 | 38 |

| 10" | 250 | 114 | 250 | 695 | 387 | 324 | M27 | 16-29 | 58 |

| 12" | 300 | 114 | 285 | 830 | 451 | 381 | M30 | 16-32 | 81 |

| 14" | 350 | 127 | 320 | 900 | 514 | 413 | M30 | 20-32 | 119 |

| 16" | 400 | 140 | 355 | 980 | 591 | 470 | M33 | 24-35 | 149 |

| 18" | 450 | 152 | 380 | 1030 | 628 | 533 | M33 | 24-35 | 198 |

| 20" | 500 | 152 | 415 | 1110 | 686 | 584 | M33 | 24-35 | 215 |

| 24" | 600 | 178 | 475 | 1305 | 813 | 692 | M39 | 24-41 | 436 |

| 30" | 750 | 229 | 580 | 1525 | 997 | 857 | M45 | 28-49 | 528 |

| 36" | 900 | 241 | 680 | 1765 | 1168 | 1022 | M50 | 32-52 | 843 |